What is the difference between mill finished aluminum and anodized aluminum?

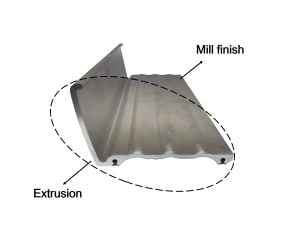

Both are aluminum extrusion technical term and both products are extrusion products in the mill.

For any questions or you want to know more about mill finishing and anodizing, reach us today! We are ready to help you. If you are looking for a ladder to meet your requirements, please don’t hesitate to contact Step by Step! We have a huge range of ladders and spare parts too!